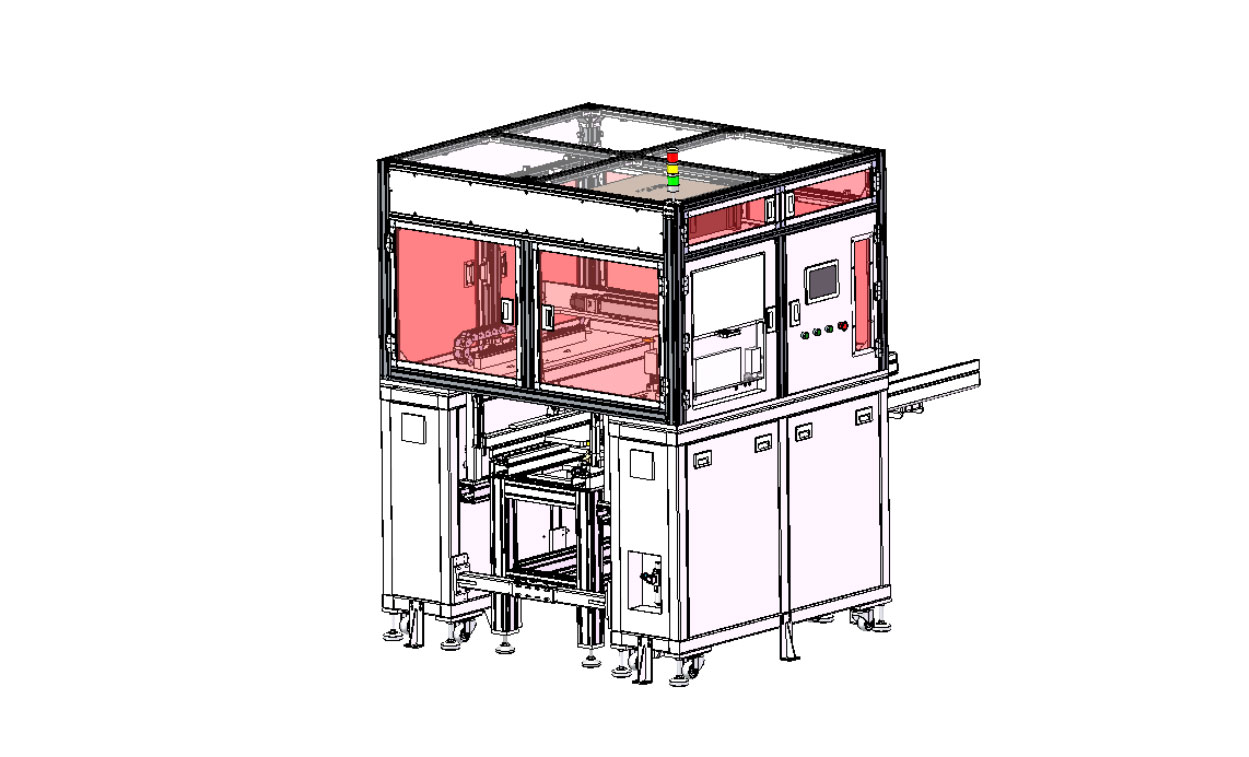

Sealing nut defect visual inspection equipment

On-line detection of defects in the welding process of sealing nut

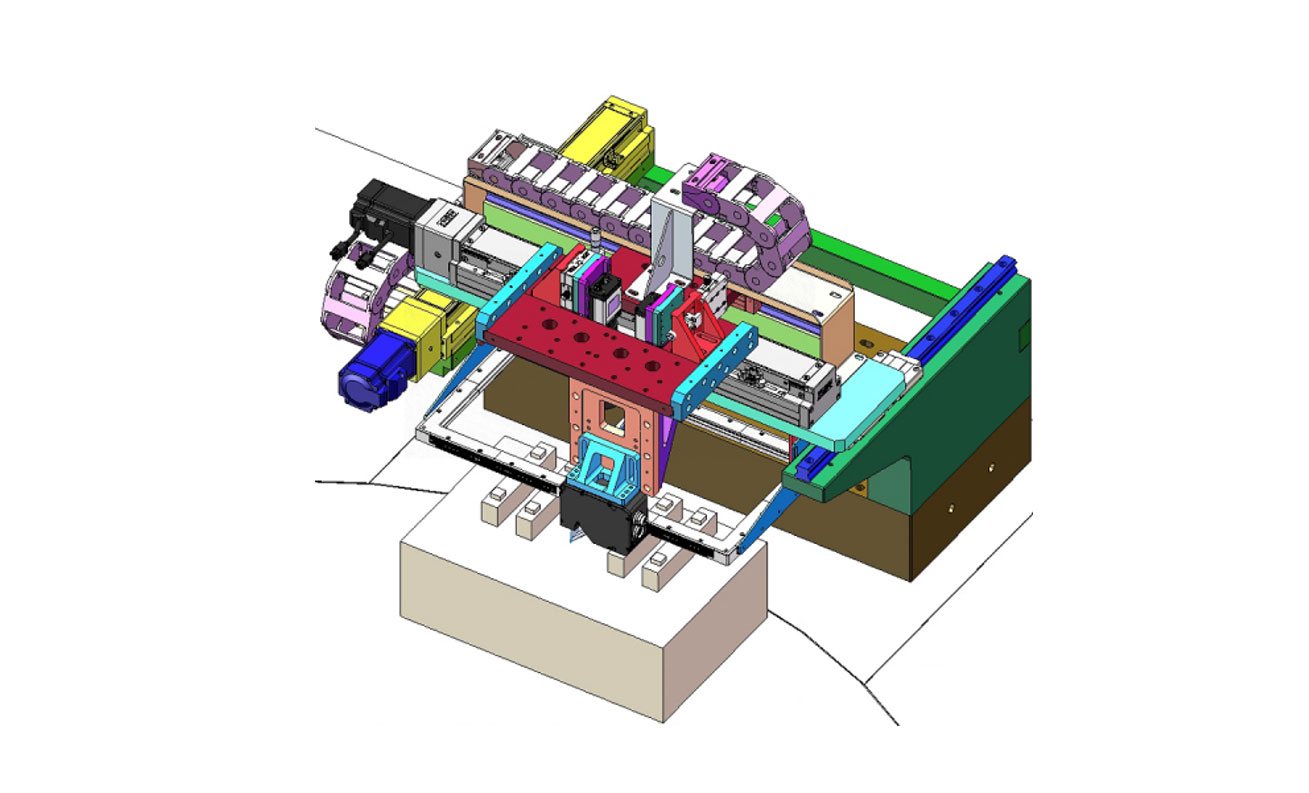

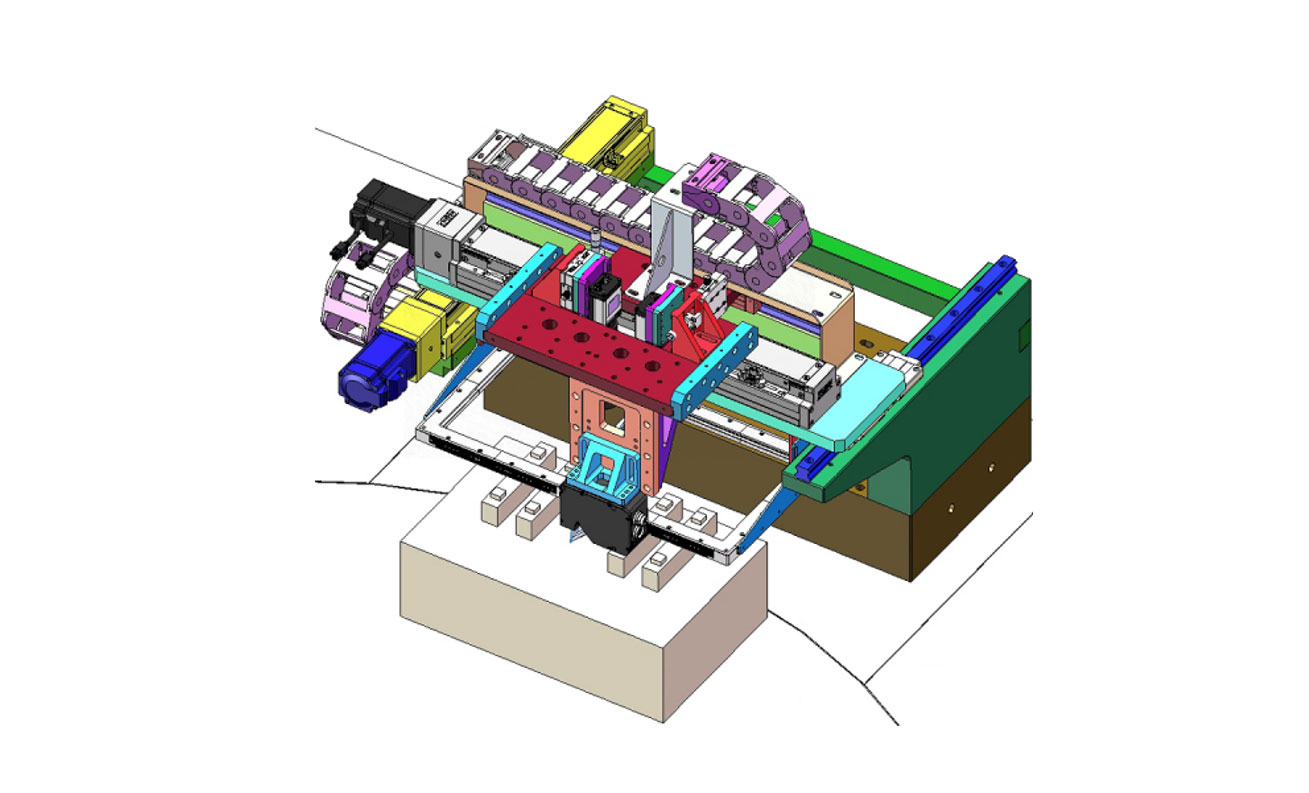

Equipment Introduction

In the production process, it can detect whether there are defects in the sealing nail welding, such as bad steps, pinholes, burst points, broken welding, welding slag, welding nails, partial welding, non-welding and other bad defects. Realize surface defect detection and automatic defect classification, data storage analysis, ng alarm and other functions

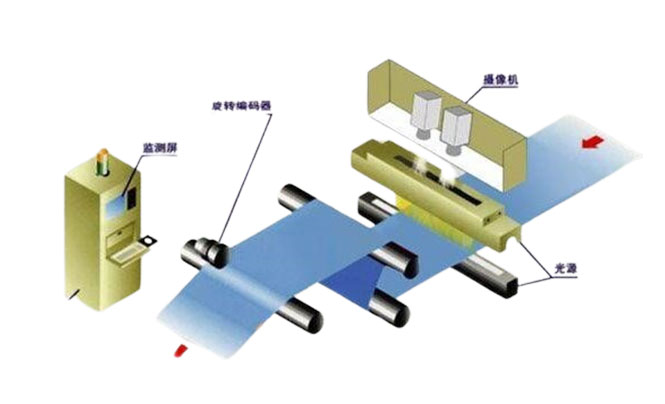

Key technology

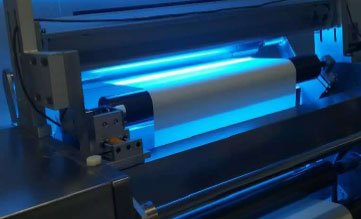

The combination of high-performance 2D camera and 3D camera enables continuous detection of defects in the production process, and the combination of traditional image processing algorithms and AI artificial intelligence algorithms enables accurate identification and automatic classification of defects, with a false negative rate of 0%.

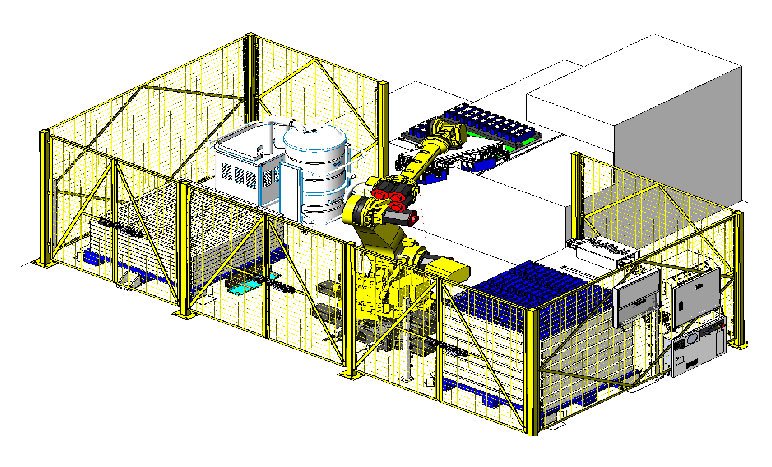

Application scenarios

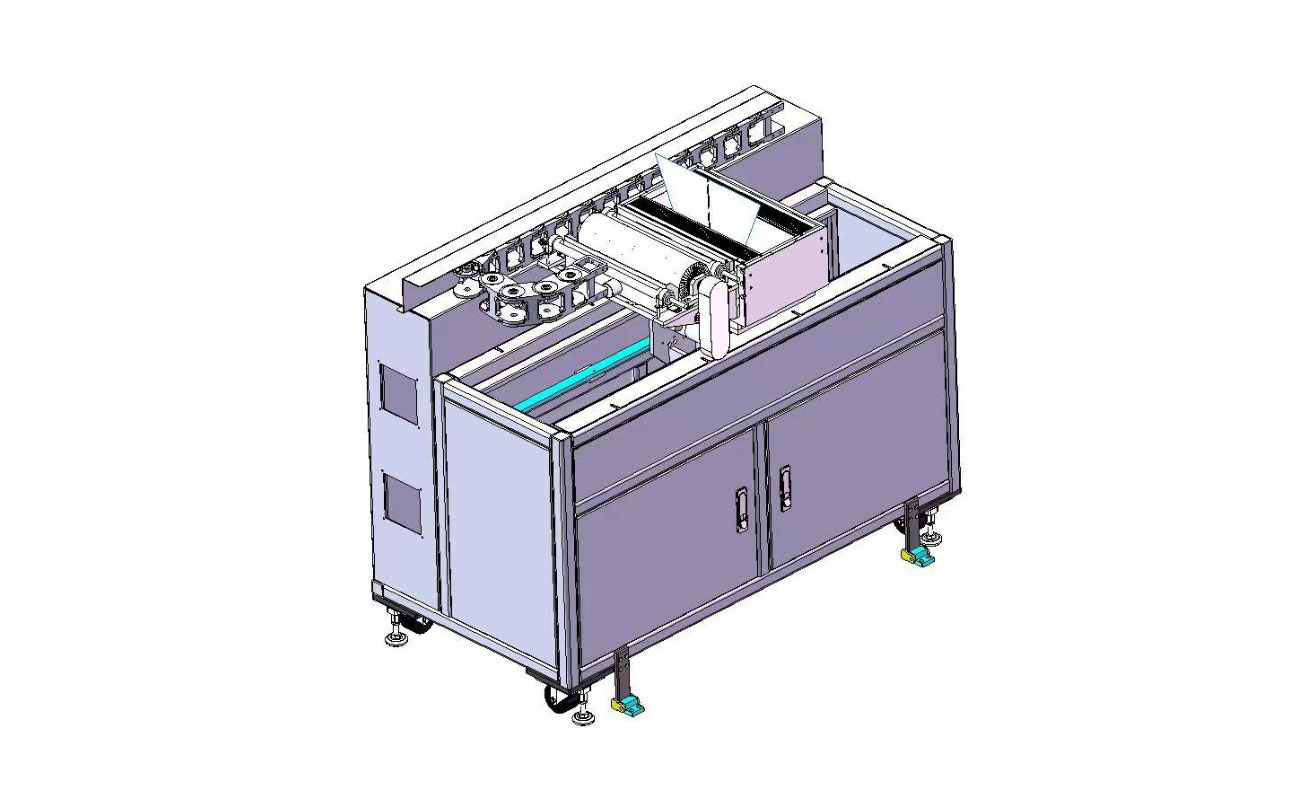

| Device Function | On-line detection of defects in the welding process of sealing nut |

| Range of application | Sealing nut welding appearance inspection |

| Detection content | Bad steps, pinhole, burst point, broken welding, welding slag, welding nail, partial welding, non-welding, etc |

| Loading and unloading method | Docking production line, fully automatic loading and unloading |

| Efficiency of productivity | 15ppm |

| False negative rate | 0% |

| False positive rate | ≤0.5% |

Other Related Solutions