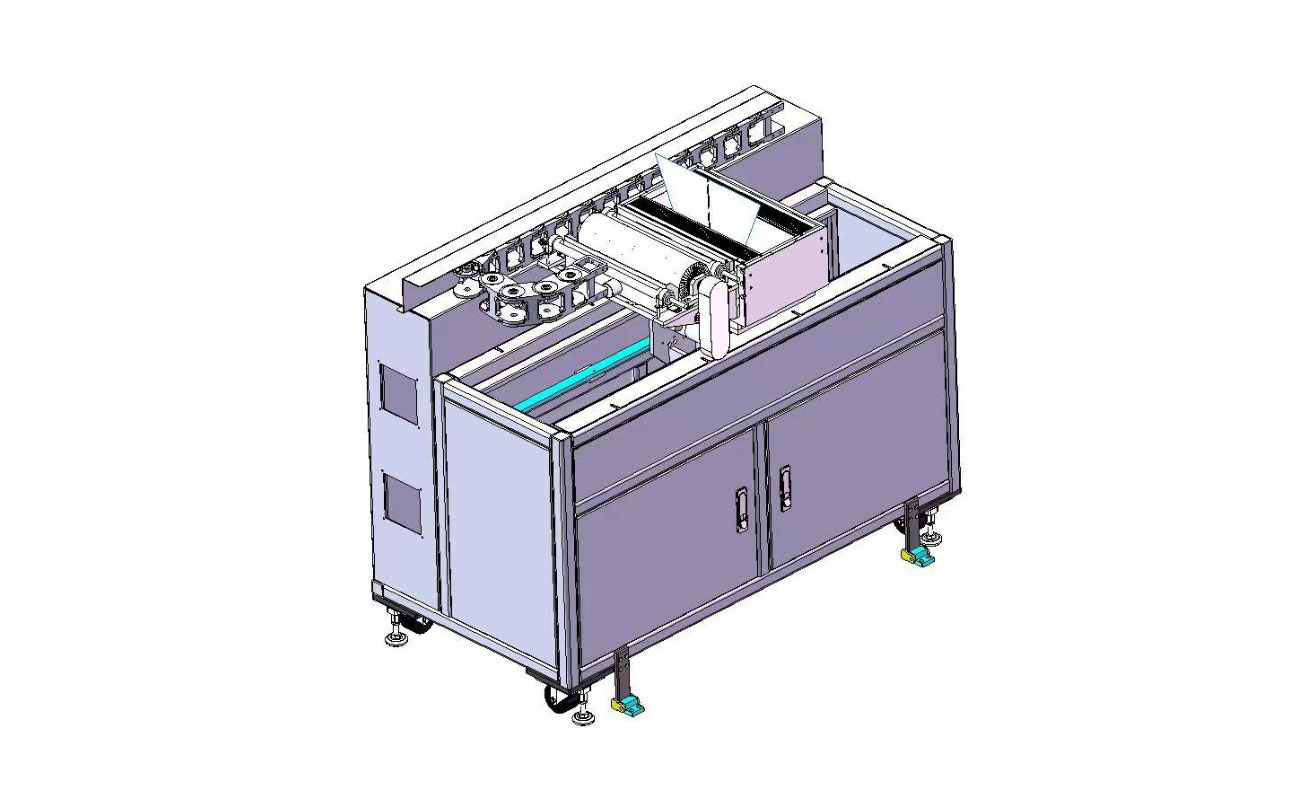

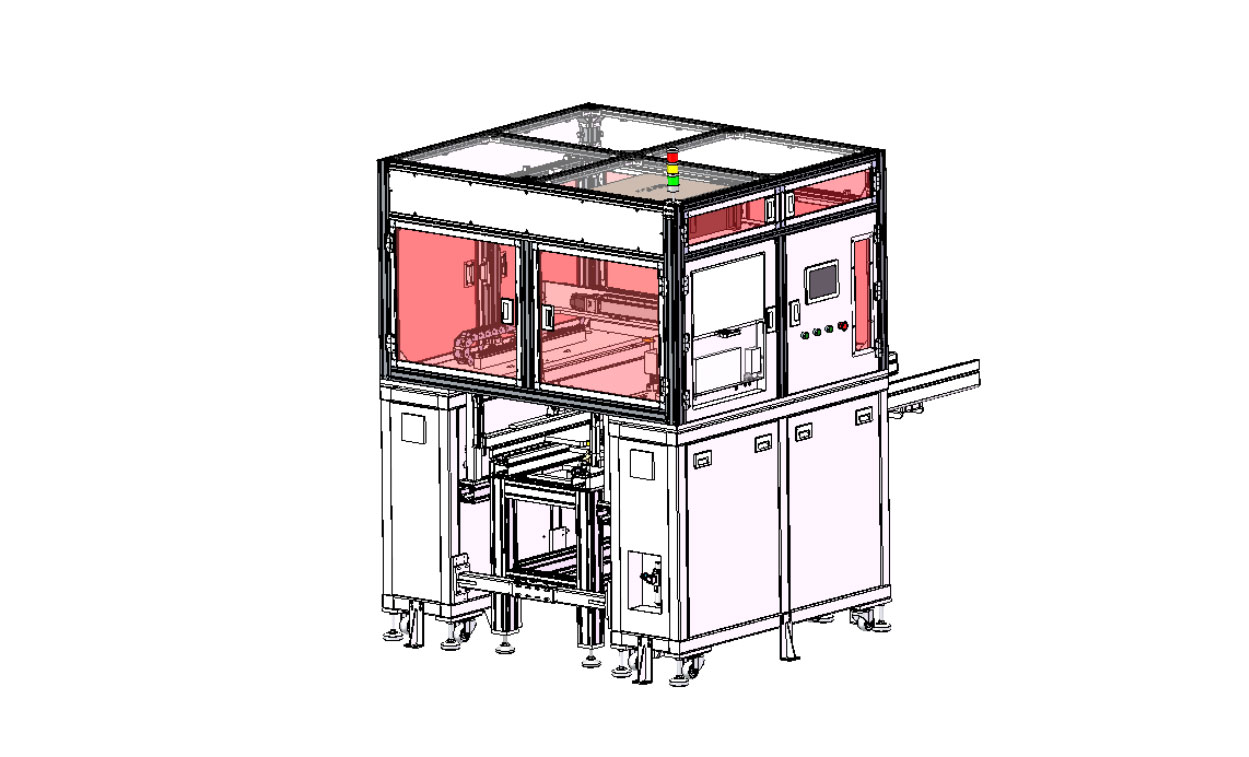

Isolation film defect visual inspection equipment

1.On-line detection of defects in isolation film production

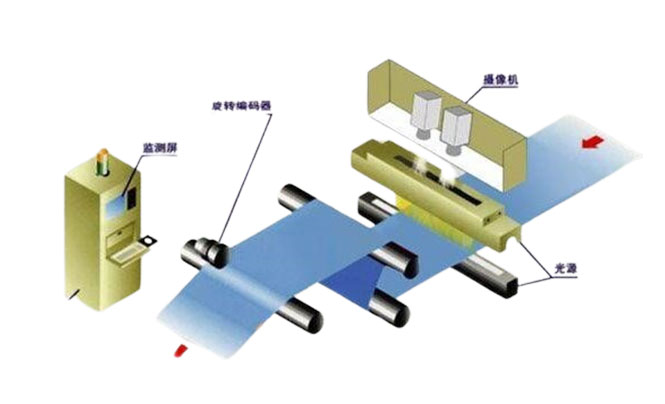

2.It can detect whether there are defects in the isolation film during the production process, such as pinholes, missed coating, black spots, creases, and other bad defects. Realize surface defect detection and automatic defect classification, data storage analysis, ng location labeling and other functions

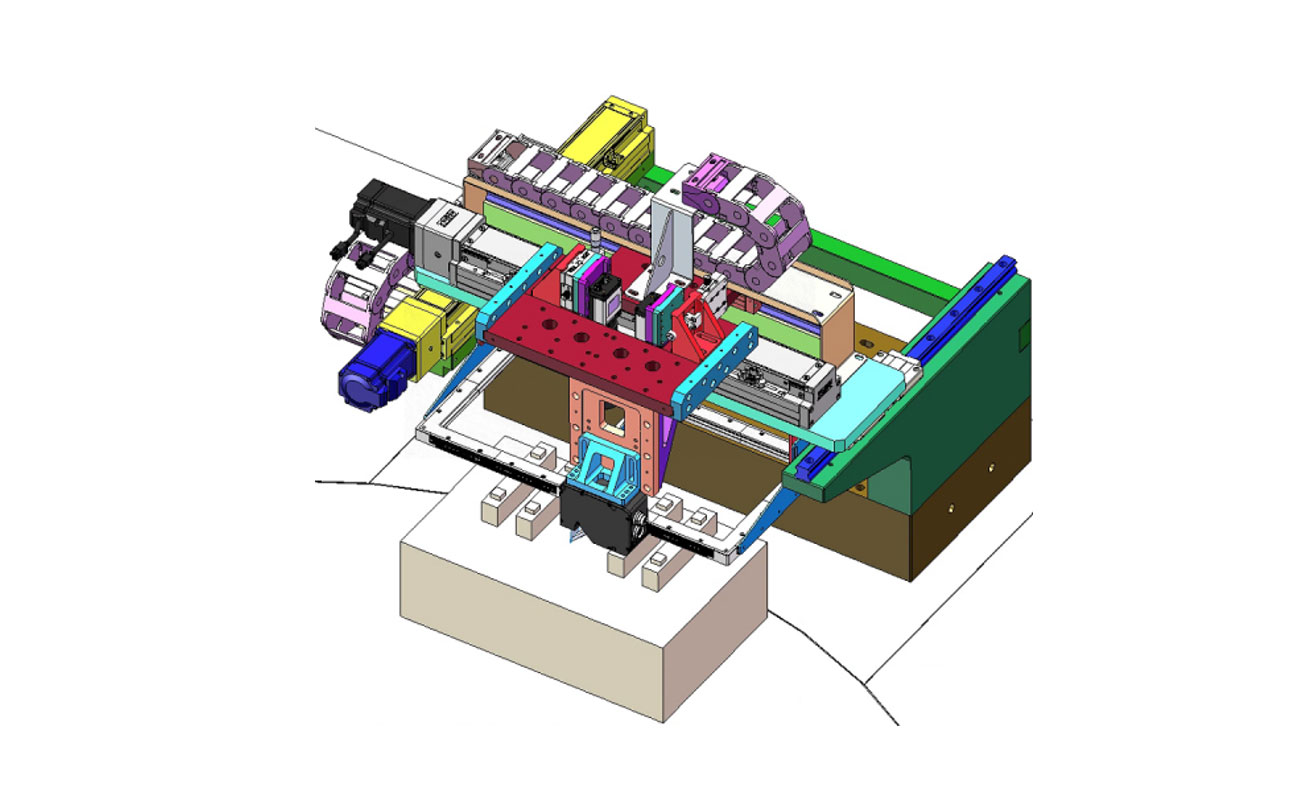

3.The high performance 8K line scan camera and high light source are used to achieve continuous detection of defects in the production process, and the traditional image processing algorithm and AI artificial intelligence algorithm are combined to achieve accurate identification and automatic classification of defects, and the false negative rate is 0%

The high performance 8K line scan camera and high light source are used to achieve continuous detection of defects in the production process, and the traditional image processing algorithm and AI artificial intelligence algorithm are combined to achieve accurate identification and automatic classification of defects, and the false negative rate is 0%.

| Device function | Detection of isolation film defects |

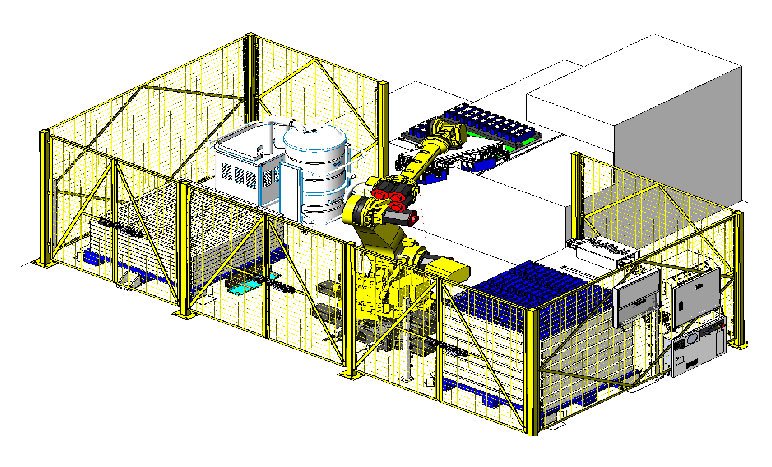

| Range of application | Isolation film, copper foil, aluminum foil coating appearance inspection |

| Detection content | Width, alignment, defects |

| Loading and unloading method | Docking production line, fully automatic loading and unloading |

| Loading and unloading methods | Docking production line, fully automatic loading and unloading |

| Efficiency of productivity | ≤120m/min |

| False negative rate | 0% |

| False positive rate | ≤0.1% |