Prognostic and Health Management

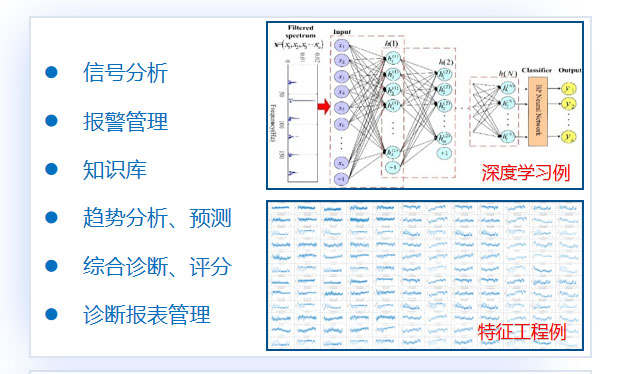

Vibration signal:Time-frequency sensing technology, TsuC-LS feature matching technology, feature engineering technology, proprietary diagnostic model for high speed, low speed and variable operating conditions;

Electrical signal: CT transform technology, body analysis technology;

Sound signal: low speed heavy duty equipment fault diagnosis technology;

Acoustic emission frequency: low speed and high precision fault diagnosis technology Signal analysisAlarm managementKnowledge baseTrend analysis, pre-AustraliaComprehensive diagnosis and scoringDiagnostic report management.

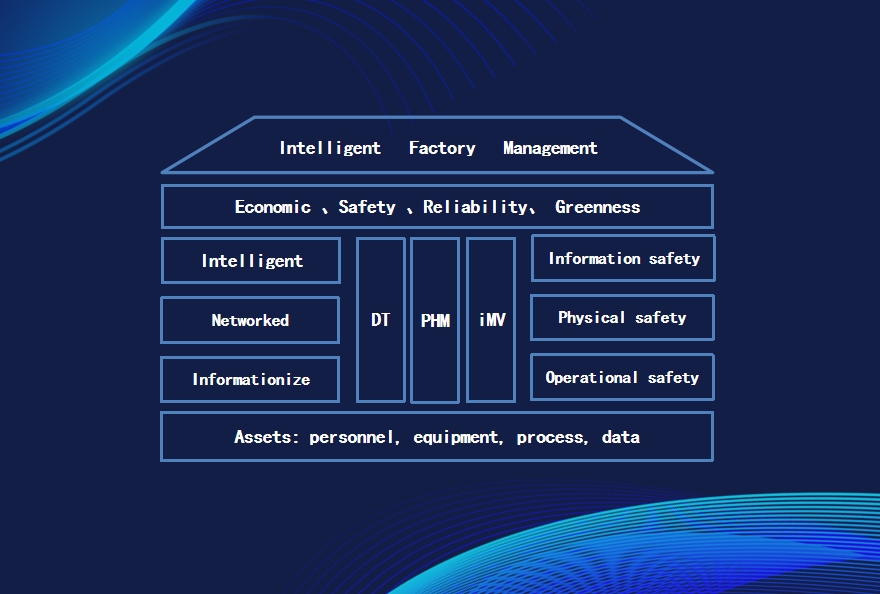

Main industry:High-value, mechanical-model complex equipment and industries with high safety requirements: rail transit, Power equipment, petrochemical, military and other fields. The equipment value is high enough, the impact on production, the mechanism model is more complex but large civil industries: CNC machine tools, water conservancy, paper industry, power and energy systems.

Main equipment:Elevator, belt conveyor, steam turbine, gas turbine, centrifugal compressor, reciprocating compressor, screw compressor, centrifugal fan, axial fan, Roots fan, centrifugal pump, reciprocating pump, axial flow pump, screw pump, transmission, etc.